Pro® Fast, the Versatile Velcro Tape with a Convenient Dispenser

Our Pro® Fast Hook & Loop Tape & Dispenser is one powerful and versatile fastening solution, in a small, convenient box. Our Pro® Fast Dispenser boxes combine, quality, small size, ease of application and are extremely economical.

Introducing Pro® Fast Hook & Loop

Pro® Fast Hook & Loop Tape is the tool for the job whenever you need to stick two parts or pieces together, temporarily, repeatedly, or permanently.

Pro® Fast Hook & Loop Tape allows you to combine the power of the permanent adhesive backing, with the functionality of temporary hook & loop fastener holding, similar to velcro.

What’s in the Box?

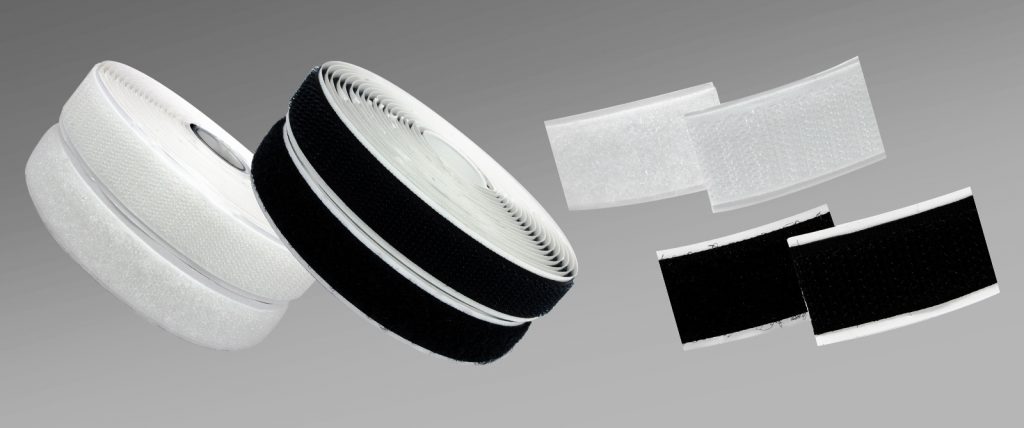

Each Pro® Fast Dispenser box contains one roll each of the highest quality hook and loop fasteners, with a pressure sensitive rubber based adhesive system. Available in Black and White colors.

The permanent adhesive backing on our Pro® Fast hook & loop rolls adheres easily to a wide variety of surfaces, including plastic, wood, metal, fabric and more.

Pro® Fast Hook & Loop is Perfect for Professional or Personal Use

Whether you are an exhibitor at a trade show, a teacher, A-V department, school, church, party supply or looking to customize your own holding and fastening solutions around the home, office or garage, you will love the convenience Pro® Fast Hook & Loop tape provides.Â

Lets’s take a closer look at what makes Pro® Fast a high quality velcro tape:

Quality Materials

Hook and Loop fasteners come in many different grades.

Pro® Fast Dispenser boxes contain a roll of hook and a roll of loop that are 100% nylon. This gives them extraordinary endurance to adhering and removing many times without the performance diminishing.

The rubber based adhesive is the highest quality and will adhere to many different surfaces permanently.

Convenient Size

Pro® Fast Dispenser boxes take up very little space in your storage areas or tool or equipment boxes.

Pro® Fast Dispenser boxes are only 2†deep and about 5†wide and 5†high. Each box contains 15 feet of pressure sensitive hook and 15 feet of pressure sensitive loop fasteners.

Whether you are an exhibitor at a trade show or a teacher in a classroom, you’ll see how easy it is to find a convenient place to store our Pro® Fast Dispenser boxes so they’re in reach, right when you need them.Â

Ease of Application

Pro® Fast Dispenser boxes have 2 die-cut holes that you can feed your hook and loop rolls through. This makes it easy to pull as little or as much of each that you need at that particular time. Pull the hook or loop tape through, cut with a scissor, and apply!

The remainder of the rolls stay in the box, keeping them neatly wound (instead of unwound all over your workspace) and ready for your next use. This feature of the dispenser box makes it particularly convenient for D.I.Y. and arts and crafts projects, too.

Cost Efficiency

Pro® Fast Dispenser boxes contain both the hook and the loop fasteners to complete a full 15 feet of attaching. If you were to buy these rolls individually, they would be much more expensive and you would need both separate rolls to get the job done.

For those who work in trade shows, here’s a size comparison for you: Fifteen feet is enough to affix a drape on a 10 foot trade show table with 2 feet on each exposed side. If you were to buy similar size rolls of hook and loop adhesive backed fasteners at the trade show, it would cost many times more to do the same job.

Questions?

Please reach out to Dennis Mirabella, Director of Business Development for Arts & Entertainment & Graphic Arts, at

Compared with large complex thin - wall castings, civil products have lower requirements on casting quality. However, for the latter, shorten the production cycle, improve the production efficiency of the problem becomes more prominent. The gelation process of common silica sol mainly depends on the dehydration and drying of silica sol, which takes longer time than the gelation of chemical hardening ethyl silicate. Ethyl silicate shell using ammonia dry each layer can be completed in 2h, and the final hardening of silica sol generally takes more than 12h, for some deep holes and other difficult to dry parts of the need for a longer time. At the same time, because the Investment Casting shell needs to be made in layers, each layer needs to be fully dried, to ensure that the lower shell immersion coating will not cause the problem of remelting off, and immersion coating itself, water will be immersed in the dried shell, resulting in a long overall drying cycle. It is a schematic diagram of the production cycle of silica sol shell investment casting under general conditions. As can be seen from the figure, shell making time accounts for more than 50% of the whole casting production cycle. To shorten the delivery time and shell making cycle is the core of the problem. The key factors to shorten the shell-making period can be divided into two aspects: internal cause and external cause. The main internal cause is the characteristics of the binder, and the external cause is the drying condition.

Silica Sol Casting industry in China is developing rapidly and its application is also very extensive.

Tianhui Machine Co.,Ltd , https://www.thcastings.com